- The operation of the textile industry from January to October 2024!

- Automotive interior non-woven fabric how to choose?

- Advantages of automotive interior non-woven fabrics

- Textile industry leads new quality productivity!

- Application of automotive interior non-woven fabric

- The operation of the textile industry from January to August 2024!

- Contact: Mr Li

- Tel: 0086-139 2680 4227

- Fax: 0086-0769-85080625

- Email: xh@xhnonwovens.com

- Add: No. 15, Baihao Industrial Street, Houjie Town, Dongguan City, Guangdong Province

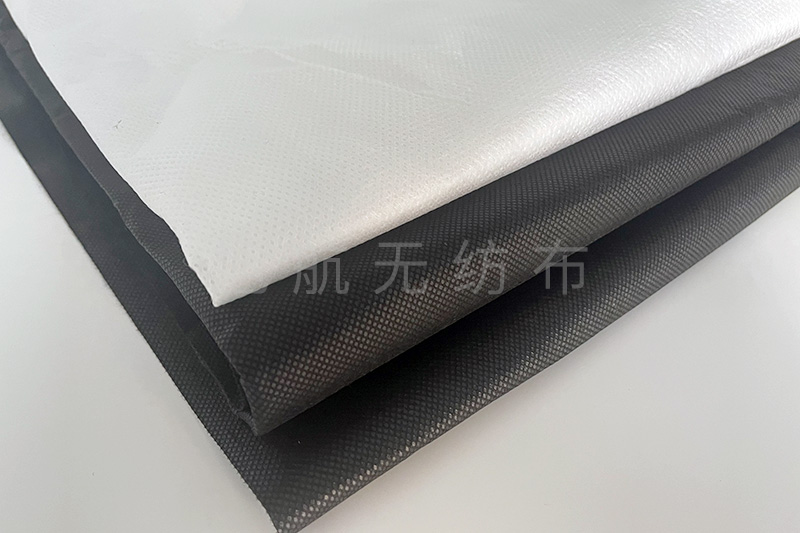

Non-woven geotextile is also called non-woven geotextile, which belongs to a kind of non-woven geotextile. Its characteristic is that there is no need for weaving. The non-woven geotextiles we often say are mainly made through repeated needle punching processes. Therefore, some non-woven geotextiles are also called needle-punched geotextiles, and they are mainly classified into two types, namely Filament needle-punched geotextile and staple fiber needle-punched geotextile.

Since the non-woven geotextile is made by repeated needle punching, it has many characteristics that other geotextiles do not have. For example, the pore structure is a three-dimensional state, which also determines that the non-woven geotextile has very good water permeability, so it It is also called permeable geotextile. The pore size range of different geotextiles is also different, so the water permeability is also different.

Introduction of 5 functions of non-woven geotextile

Compared with woven geotextiles, non-woven geotextiles are more popular. In fact, there is no shortage of them because of their good functions and performance. Here is a brief introduction.

1. Non-woven geotextiles can be used for road construction, not only to prevent water from washing away the soil, but also to prevent uneven settlement of the foundation;

2. In terms of road repair, it can repair cracks on the one hand and delay the occurrence of road cracks on the other hand;

3. Non-woven geotextiles can be used as drainage materials for subway tunnels, using geotextiles with good permeability and flat drainage;

4. It can be used as an isolation layer, if different materials are piled together, in order to keep the overall structure without mixing layers, non-woven geotextiles can be used for isolation.

5. Non-woven geotextiles can also be compounded with some plastic films to form impermeable materials. However, the non-woven geotextiles here mainly play the role of protecting the plastic film, and of course it will occasionally play its role in drainage.

Up to now, nearly 70% of the geotextiles used in major projects are chemical fiber geotextiles, which is what we often call geotextiles made of polymers, while natural fiber geotextiles are rare, even Many people don’t know that there are artificial fibers.

What is natural fiber geotextile

What is a natural fiber geotextile, that is, a kind of geotextile made from cotton, hemp, coconut husk, straw and other plant fibers with good toughness, and then through a variety of production processes. This kind of geotextile is mostly used in artificial grass planting, urban afforestation, desert edge management, etc., because it has a relatively large impact on ecological engineering, so to a certain extent, relevant departments also pay more attention to natural fiber geotextile.

What are the advantages of natural fiber geotextile in the process of use, we know that the raw materials of natural fiber geotextile come from nature, so its compatibility with the ecological environment is relatively good, although its durability is still lacking, but after use It can be easily degraded by microorganisms, not only does not pollute and destroy the environment, but also provides corresponding feed for some plants. And chemical fiber has many mechanical properties and hydraulic properties, natural fiber geotextile also possesses.

Introduction of Geotextile Application Engineering

Whether it is natural fiber geotextile or chemical fiber geotextile, it will not cause pollution and harm to the ecological environment, and because of its good performance, the shadow of geotextile can also be seen in many projects.

Environmental restoration projects: common ones include the planting of greenhouse vegetables, the treatment of weeds in agriculture and gardening, the improvement of soil in the grain base, etc.;

Water conservancy projects: common seepage prevention measures for dykes and dams, seepage prevention for planting of flowers and plants on the roof of buildings, and seepage prevention for subway and other tunnel projects;

Ecological engineering: There are many applications in this area, such as anti-seepage treatment of landfills, reservoirs built in arid areas, anti-seepage treatment of artificial lakes, water retention treatment of slope protection, lawns, etc.;

Road engineering: The common ones are road, railway, airport runway, sports ground runway foundation reinforcement, drainage treatment and so on.

- Automotive interior non-woven fabric how to choose?

- The operation of the textile industry from January to October 2024!

- Advantages of automotive interior non-woven fabrics

- Textile industry leads new quality productivity!

- Application of automotive interior non-woven fabric

- The operation of the textile industry from January to August 2024!

- Automotive interior non-woven advantages of non-woven fabric

- The global economic recovery has held up better than expected

- From January to August this year, the total profit of China's textile industry was 100.62

- If there is a need for automotive interior non-woven fabrics, please contact us!